|

| |

Process Improvement:

We specialize in energy systems, power cycle chemistry and

water treatment, for any industry. Although utility systems may not be a

profit centre, paying attention to your utility systems can yield attractive

returns. The US Department of Energy has stated that an energy audit and improvement program for a typical industrial

facility can save 20% in steam related costs. In the USA alone, this would

save

US$4 Billion dollars per year and avoid approximately 32 million tonnes of emissions

reduction. Typical savings that we can help

your organization achieve include:

- 10-12% improvement by improving water treatment program

to prevent formation of insulating boiler scale.

- Minimizing stack gas energy losses (improve boiler

efficiency by 1% for each 15% reduction in excess air or 1.3% reduction in

oxygen, or, for each 40 degrees F stack gas temperature reduction).

- Improve recovery of condensate and it's heat content.

- 10-15% energy savings can be realized when steam traps

are actively maintained.

- 2-5% with boiler and auxiliary equipment tune-ups.

- 3-13% savings may be realized with improved insulation.

- Cooling water system audit and tune-up may improve heat

transfer rates and heat exchanger water side cleanliness to increase plant

production rates, extend equipment life, and virtually eliminate downtime

for heat exchanger cleaning.

Quantification of the savings opportunity is a key first

step towards achieving your plant's full potential. Often this is not

done as water and energy costs appear small on a company's balance sheet, and

many may see it as an uncontrollable cost of doing business.

Utility operation reliability is of much higher importance. Implementation of efficiency improvements typically also enhance the system's

reliability. We will help you to reduce costs and improve reliability to

help achieve your

plant's full potential.

For

new assets, utility system detailed design work typically begins last,

yet construction must be completed first. Design activity is concentrated within a short time

frame, requiring increased staff hours for a short period. This is a key

time, as up to 80% of a

project's capital expenditure is typically determined at this stage. Significant savings can

be realized, by applying specialized experience early in the project

phases. At this in the design, DeltaCascade's service provides the highest

value. For

new assets, utility system detailed design work typically begins last,

yet construction must be completed first. Design activity is concentrated within a short time

frame, requiring increased staff hours for a short period. This is a key

time, as up to 80% of a

project's capital expenditure is typically determined at this stage. Significant savings can

be realized, by applying specialized experience early in the project

phases. At this in the design, DeltaCascade's service provides the highest

value.

Water

systems are essential to industrial

installations, whether it be influent water, boiler

water, steam or condensate, cooling water, process water, or wastewater

systems. Used as a heating or a cooling agent or as a feed stock, effective design and operation of water

systems is likely

critical to your operations. systems is likely

critical to your operations. Yet, in most

industries, as water related systems are typically not

identified as profit centres, water related

opportunities for improvement are often overlooked. DeltaCascade can help

you identify and quantify undiscovered opportunity for improvement, often of significant proportion. Process

Improvement Services (Operating

Facilities)

| Water System Audits for

Process

Improvement Opportunity Identification

|

Influent Water Systems |

| Boiler Water, Steam and Condensate Systems |

| Cooling Water Systems |

| Wastewater Systems |

| Energy System Audits for Process

Improvement

|

Steam system audit to optimise energy use and

water use (eg: minimize

venting) |

| Scale and corrosion protection

enhancement |

| Integration Opportunities

|

Site

energy and water system mass balance

modelling, needs

assessment, improvement opportunity identification and implementation |

| Plant Start-up

and Shutdown/Turnaround Assistance |

Chemical cleaning and passivation coordination |

| Commissioning |

| Equipment Lay-up |

| Training

|

Operator Process Training |

| Statistical Process Control

and Quality Improvement |

| Procedures and Manuals Development |

| Process Design,

Procurement and Construction

|

Implementation

of Identified Improvement Opportunities |

Typical Benefits

| Increased Revenue |

Increase plant production rates |

| Extend run time between shutdowns |

| Improve plant reliability |

| Improve process input quality |

|

Reduced Costs

|

Reduce chemical and mechanical inputs |

| Reduce process waste |

| Improved Environmental

Performance

|

Reduce effective greenhouse gas emissions |

| Improve plant effluent water quality |

| Reduce plant effluent water quantity |

| Reduce plant water demand |

Sample

Water System Opportunities: Sample

Water System Opportunities:

Influent

Water Systems Influent water quality and treatment is key to

effective, optimal operation of all downstream equipment. Problems and

opportunities encountered might include:

- Supply Water: If supply water quality varies, such as with river water

intakes during seasonal run-offs or storms, seasonal adjustments to process

operations may be required. This maybe as simple as drawing from

holding ponds instead of river during peak spring-run off periods, or

changing a cold lime softener to clarification only mode by interruption of

lime feed. Backwash rates of filters and other packed beds such as ion

exchange vessels, must be reduced in winter and increased in summer to

account for temperature and viscosity changes. A system audit may

uncover some simple improvements that may have been overlooked.

- Clarification: If you clarify influent water, and have poor

or variable performance, a clarifier audit may be of value. Audits

will review operating practice identifying improvements, in areas such

as: water flow control, temperature control, chemical feed control, sludge level

control and chemical treatment regime.

Pilot tests or jar test

studies can also be performed.

- Lime Softening: Performance improvement of these units

greatly improve performance of downstream systems, such as demineralisers

for boiler make-up water supply. Lime slurry feed

problems may present improvement opportunity. One plant added heat

exchange to raise softening temperature, which improves softening

ability. However, temperature control was overlooked, resulting in

temperature inversions in the softener, and severe intermittent sludge carry-over

problems. Installing temperature control reduced average temperature

increase, but alleviated the upset problem and improved overall performance.

As for clarification, an audit may enable significant improvement in asset performance.

- Demineralisation: Demineralisation plants are a work horse of

industry. As they operate in a semi-batch mode, they can be challenging to

troubleshoot. Performance degradation must be monitored, managed and

minimised. Ion exchange resins must be kept clean, and, particularly for

anion resins,

typically must be intermittently cleaned to

minimise irreversible fouling. Demin plant audits can identify needs

and improvement opportunities, such as reducing wastewater production and

reducing caustic and acid regenerant coonsumption. Training courses can similarly assist. anion resins,

typically must be intermittently cleaned to

minimise irreversible fouling. Demin plant audits can identify needs

and improvement opportunities, such as reducing wastewater production and

reducing caustic and acid regenerant coonsumption. Training courses can similarly assist.

One demin plant installation committed a simple act of discharging alkaline anion-regeneration waste to their

neutralization sump prior to discharge of acidic

cation-regeneration waste. The result was a milky precipitation of alkaline

salts which did not settle but did collect nearer to the bottom of the vessel.

This caused difficulty with waste water pH control, with additional caustic

feed for neutralization. Downstream effluent ponds experienced mysterious pH

rises during recirculation prior to discharge, due to slow re-dissolved of

alkaline precipitates. In addition to control problems, this led

to costly dredging operations at effluent water ponds to be required.. A simple fix in the demin plant operation procedures,

is to ensure that acidic waste is discharged to neutralization tank prior to alkaline

waste. This would avoid downstream pH control

difficulties due to formation of alkaline flocc.

- Reverse Osmosis or other treatment process may be required,

particularly for high pressure boilers when supply water is high in

colloidal silica or very high in dissolved solids. Water quality

control at and upstream of the RO system is key to optimal RO process

operation, otherwise, membrane life may be reduced, and RO operation costs

skyrocket. Minimization of RO reject stream is also important to

reduce wastewater production and related costs, balancing against shortened

membrane life.

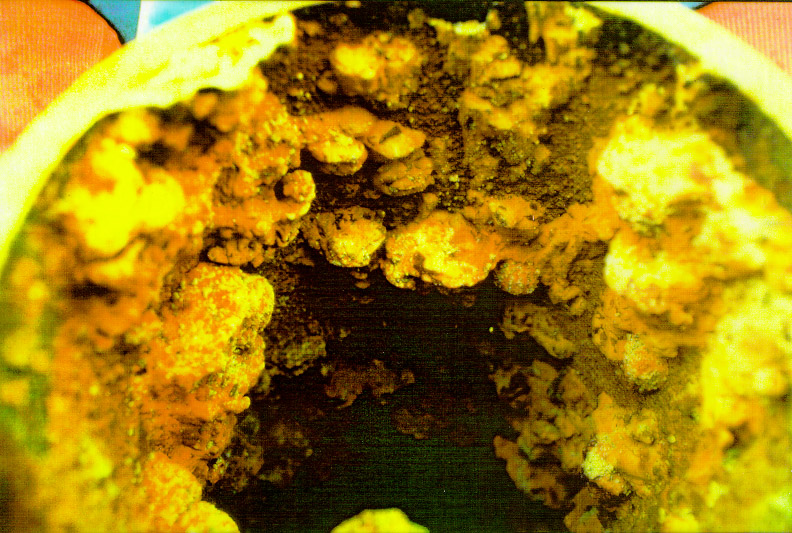

Boiler Water Systems

Steam

cycle chemistry plays an important role in efficiency and reliability of boiler

systems, as well as steam and condensate systems. If boiler tube failures are

interrupting your production or extending your planned shutdown periods, you may benefit from a boiler water system

audit. Your problem may be as simple as oxygen saturated water

contamination of condensate causing corrosion, and subsequent deposition of iron

deposits on boiler tubes.  The insulating iron deposits lead to tube overheat and

failure. The insulating iron deposits lead to tube overheat and

failure.

One facility was found to be using a low pressure boiler water treatment

product for a higher pressure boiler with a steam super-heater and steam

turbine which required high purity steam. Super-heater tube failure frequency

was increasing. The treatment product contained phosphate treatment

chemical in potassium, rather than the anticipated sodium, form. Steam

purity studies using standard sodium electrode procedure indicated acceptable steam

purity. Analysing for potassium, and then modifying the boiler water

treatment program to use sodium based phosphate treatment, enabled a corrosive steam solids

contamination to be identified and controlled through improved boiler water level control.

Cooling Water Systems

Evaporative cooling towers, while efficient heat sinks, and effective water

conservers compared to once through cooling, may be the largest

water consumer and wastewater generator at your site. While

cooling systems are often designed to operate at about 8 cycles of  concentration

(12.5% blow-down), they can very often effectively operate at 12 cycles (8%

blow-down) or higher. This reduces raw water demand by over 4% and reduces wastewater

production rate by approximately one third. It may also reduce chemical

treatment program costs. In

addition, cooling water systems present excellent opportunity for integration of

processes to enable water recycle and re-use. Treated sanitary waste

water, a controlled amount of boiler blow down water, some demin plant waste waters, and other streams,

may be used as cooling system make-up water, reducing raw water demand and wastewater production. concentration

(12.5% blow-down), they can very often effectively operate at 12 cycles (8%

blow-down) or higher. This reduces raw water demand by over 4% and reduces wastewater

production rate by approximately one third. It may also reduce chemical

treatment program costs. In

addition, cooling water systems present excellent opportunity for integration of

processes to enable water recycle and re-use. Treated sanitary waste

water, a controlled amount of boiler blow down water, some demin plant waste waters, and other streams,

may be used as cooling system make-up water, reducing raw water demand and wastewater production.

Cooling water flow mal-distribution is a common problem at industrial

facilities. Numerous heat exchangers and piping networks typically

exist between cooling water supply and return headers. Hence, flow

restrictions at certain exchangers cannot typically be determined by monitoring

pressure drop. Flow restrictions may be

difficult to identify unless equipment has a high level of instrumentation. Equipment near the end of

cooling water headers are particularly prone to becoming clogged with debris, as

the debris has more difficulty taking corners, than following to the end of the

pipe. Cooling towers are essentially big air washers, so that small bore tube exchangers may become clogged following

wind storms, and remain clogged with seeds, fluff, dirt and debris, with elevated fouling and corrosion rates, until

serviced. Resulting cooling water flow reduction reduces heat exchange rates.

More seriously, the accompanying low water velocity insidiously contributes to

heat exchange surface fouling and under-deposit corrosion. Corrosion

products contaminate the entire system, compromising both corrosion control and

scale control performance throughout the entire plant. A cooling water flow survey with portable ultrasonic flow

meter can be helpful to identify problem areas for correction.

Hydraulic analysis of the entire cooling water system piping network,

particularly prior to system piping modifications or expansions, can help avoid problems of system

fouling, under-deposit corrosion and heat transfer related production

bottlenecks. When designing side-stream filters, it may be prudent to have

the filter feed water take-off from the re-circulating cooling water at the

outside of any available pipe bends, to enhance capture of debris by the filters

for the life of the plant.

Wastewater Systems

Minimization of waste water production is a primary opportunity for improving

wastewater systems performance. Optimising influent water treatment systems,  and

taking advantage of water re-use and recycle and other process integration

opportunities, can pay significant benefit. and

taking advantage of water re-use and recycle and other process integration

opportunities, can pay significant benefit.

In addition to waste water process audit in itself, quality control of water

feeding the waste treatment process presents another significant

opportunity. Eliminating slugs of impurities through process integration

and, or, quality control programs can be highly effective.

Contact us if we can help with your water system questions, or participate with

you in problem solving and process improvement work.

|